Custom Spring from Becoming Overstressed

Custom springs are vital components in many industries, providing necessary tension, compression, or torsion in various applications. However, overstressing these springs can lead to premature failure, inefficiency, and safety hazards. This guide explores effective strategies to prevent custom springs from becoming overstressed, ensuring optimal performance and longevity.

1. Understand the Material Limitations

The first step in preventing overstress is selecting the right material for your spring. Different materials have unique tensile strengths, fatigue limits, and corrosion resistance.

- Common Materials for Springs: Stainless steel, carbon steel, alloy steel, and phosphor bronze.

- Material Testing: Ensure the chosen material can withstand the operational forces and environmental conditions.

2. Design with Stress Limits in Mind

A well-designed spring takes its intended load and stress limits into account.

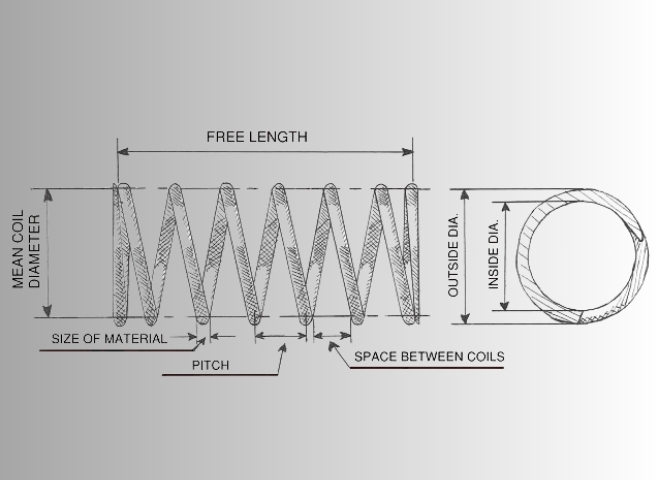

- Spring Index: Maintain an appropriate ratio of coil diameter to wire diameter to balance stress distribution.

- Safety Factor: Incorporate a safety margin to handle unexpected loads without overstressing.

- Avoid Sharp Edges: Rounded edges and smooth transitions reduce stress concentrations.

3. Optimize the Operating Environment

Environmental factors significantly impact spring performance.

- Temperature Extremes: High or low temperatures can weaken materials, reducing their load-carrying capacity.

- Corrosion Resistance: Use coatings or corrosion-resistant materials in humid or chemically aggressive environments.

- Vibration Management: Minimize oscillatory loads that can fatigue the spring.

4. Control the Load and Deflection

Overloading or excessive deflection can quickly lead to overstressing.

- Set Maximum Loads: Do not exceed the spring’s designed load capacity.

- Limit Deflection: Springs have a maximum safe deflection range; exceeding this can lead to permanent deformation or failure.

5. Regular Maintenance and Inspection

Preventive maintenance is critical for early detection of potential issues.

- Inspect for Wear and Tear: Look for signs of corrosion, deformation, or fatigue cracks.

- Replace Worn Springs: Replace springs nearing their fatigue life to avoid unexpected failures.

- Lubrication: Reduce friction and wear through proper lubrication, especially for torsion and compression springs.

6. Work with Experts

Custom springs require precise engineering and manufacturing expertise.

- Professional Spring Designers: Collaborate with professionals to design springs tailored to your application.

- Certified Manufacturers: Choose reputable manufacturers with a proven track record for quality.

7. Test Under Real Conditions

Before deploying custom springs in critical applications, test them under real-world conditions.

- Load Testing: Apply expected loads to verify the spring’s performance.

- Fatigue Testing: Simulate operational cycles to identify any early fatigue signs.

Conclusion

Preventing a custom spring from becoming overstressed is a combination of proper material selection, careful design, environmental control, and regular maintenance. By following these guidelines, you can enhance the durability and performance of your custom springs, saving time and costs while ensuring safety and reliability in your applications.